Proces Flow Diagram Haccp

The haccp team should confirm the processing operation against the flow diagram during all stages and hours of operation and amend the flow diagram where appropriate.

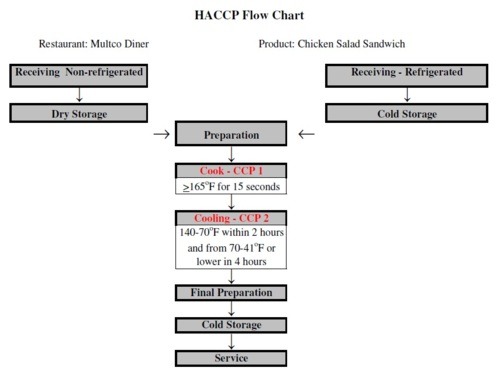

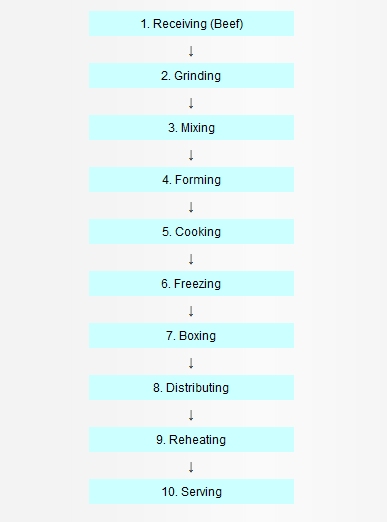

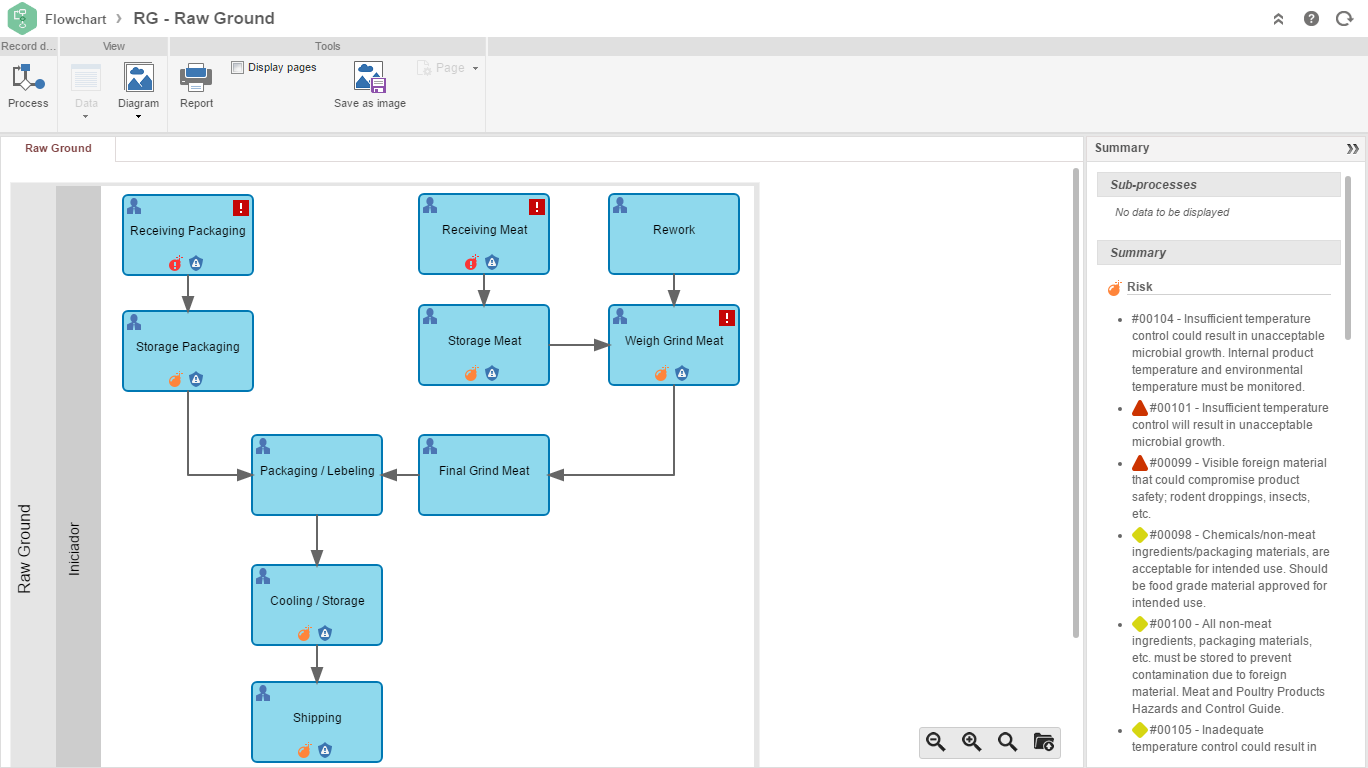

Proces flow diagram haccp. A haccp flow chart is normally constructed by a group commonly known as the haccp team or food safety team. Also including a simple schematic of the facility can be useful for understanding product and process flow. Also a simple schematic of the facility is often useful in understanding and evaluating product and process flow. A process flow diagram pfd is a type of flowchart that illustrates the relationships between major components at an industrial plant.

Begins with the evaluation of a situation to assess the possibility of consumer health hazard on the basis of three factors. On site confirmation of flow diagram. A haccp flow chart is a diagram of the process flow of a food operation from incoming materials to the end product. Its used to document a process improve a process or model a new one.

The simplest form of process flow diagram is linear. If you want to recap on the haccp basics including flow process charts check out our an introduction to haccp express learning module by clicking here. The diagram shows a simple 8 step process where one step follows the next in order. Macro flowchart top down flowchart detailed flowchart also called process map micro map service map or symbolic flowchart deployment flowchart also called down across or cross functional flowchart several leveled flowchart.

The haccp team should perform an on site review of the. Verify the flow diagram. The haccp team should perform an on site review of the operation to verify the accuracy and completeness of the flow diagram and modifications should be made to the diagram as needed. Amazing 3d powerpoint steps diagram.

1 does the product contain contaminant sensitive ingredients. The key steps in the process are identified laid out step by step and subsequently verified by the haccp team. Process flowchart process flow diagram. 2 does its manufacturing involve a controlled process step such as sufficiently high temperature ph change or other process that can.

What is a flowchart. Variation of the process flow diagram. You should create your process flow diagram so that it focuses on major plant processes and not show minor details. Its most often used in chemical engineering and process engineering though its concepts are sometimes applied to other processes as well.