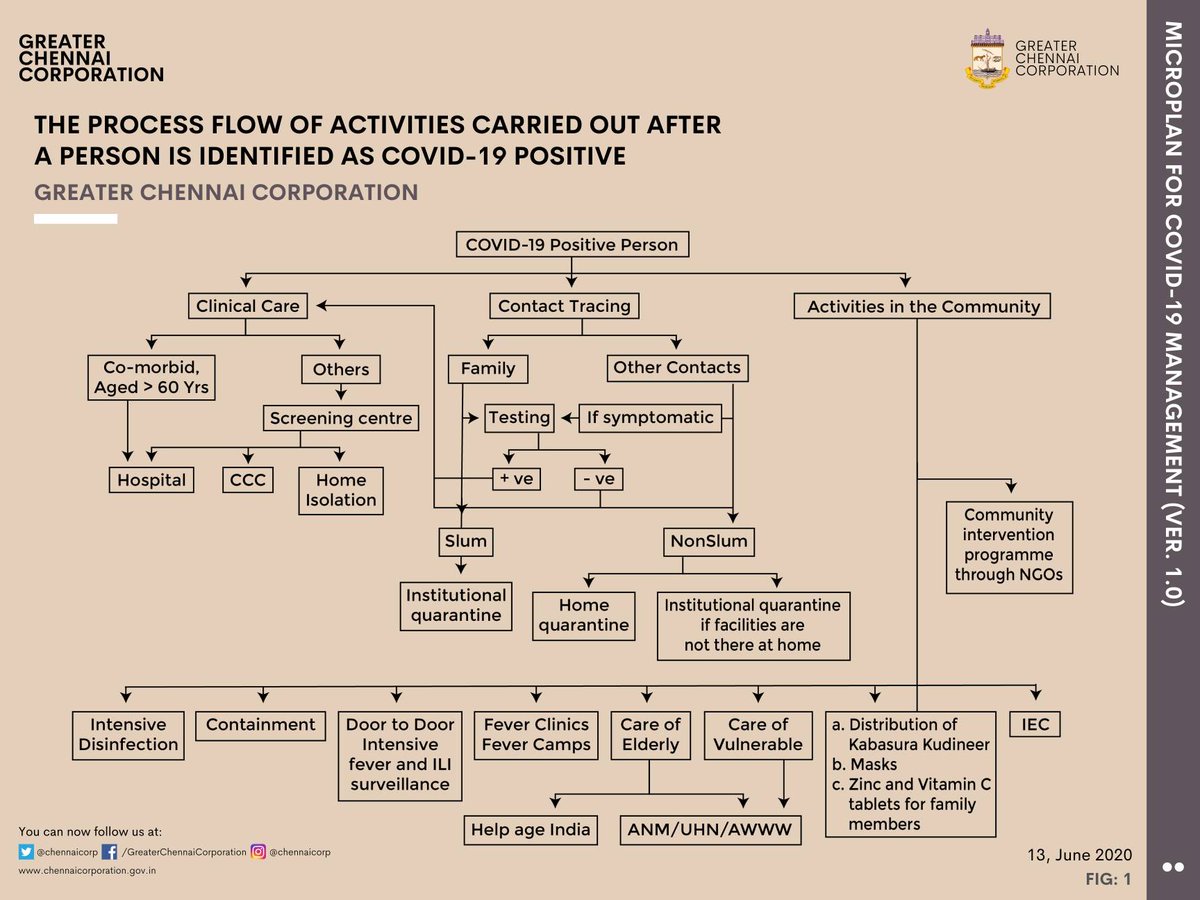

Proces Flow Diagram Of Vitamin C

For making chase nut colour d.

Proces flow diagram of vitamin c. The previous one is natural and healthy but the oil yield is much lower however oil. Pumps valves thermometers etc and temperatures at each point of the process should be collected as. The present invention relates to a process for producing vitamin b12 wherein said process comprises the steps of a culturing a strain of the genus propionibacterium in a first fermenter under anaerobic conditions to obtain a culture of propionibacterium b transferring at least part of the culture obtained in a to a second fermenter and subjecting this culture to oxygen c replacing. D the residue on the screen is recorded as dry solids not lost in water.

Vitamin b 12 was determined as follows. No part of this book may be reproduced stored in any retrieval system or transmitted in any form or by any means. The other way is chemical method that extract oil with solvents. If a continuous process is used htst a flow diagram showing each piece of equipment ie.

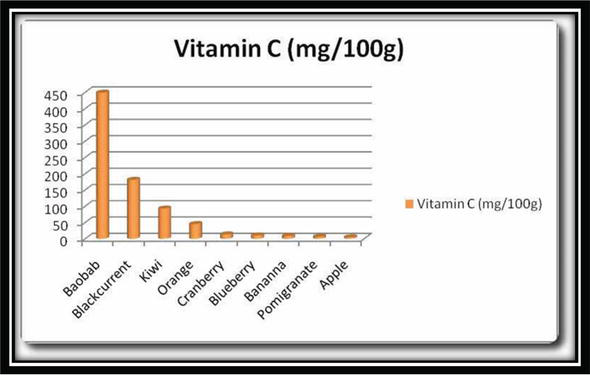

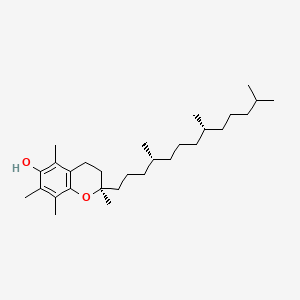

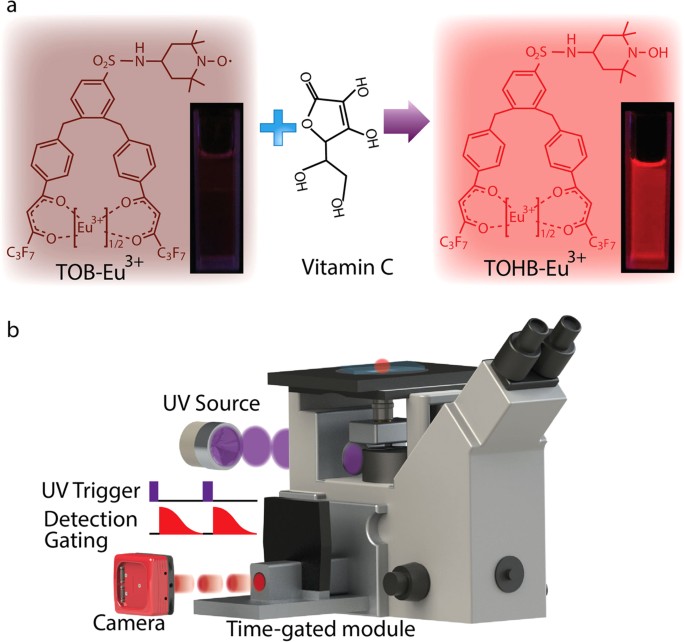

Utensil cleaning bar uses applications. Herbal creams properties of herbal cream manufacturing process of herbal cream process flow diagram 19. Vitamin c ascorbic acid l ascorbic acid finds its use mainly in food industry being a vitamin as well as an antioxidant majority of commercially manufactured l ascorbic acid is synthesized via reichstein process using d glucose as a starting material approximately 50 of synthetic ascorbic acid is used in vitamins supplements and pharmaceutical preparations. For making special brown manufacturing process process flow diagram 18.

A process flow diagram pfd is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. Another commonly used term for a pfd is a flowsheet. The pfd displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations. Higher absorption factors result in higher absorptivity into the liquid and a decrease in the number of trays required for separation however a diminishing return occurs after the absorption factor is greater than.

Where is the liquid flow rate entering the column is the vapor flow rate entering the column and is the vaporliquid equilibrium ratio for component i peters timmerhaus 2003. To extract vitamin b 12 from the cells by hot water and simultaneously convert it to a stable cn form. Manual of clinical nutrition management 2013 2011 2008 2007 2006 2005 2003 2002 2000 1997 1994 1993 1991 1988 by morrison inc a sector of compass group inc. It was bioassayed by using lactobacillus leichmannii ifo 3376 which is a.

Both two oil production methods have advantages and disadvantages. To 03 ml of the culture broth were added 45 ml of an acetate buffer ph 47 and 1 ml of kcn solution 1 gliter and the mixture was boiled for 15 minutes at more than 850 c.