Solid State Relay Wiring Diagram For Cut Out

There are two common types of relays.

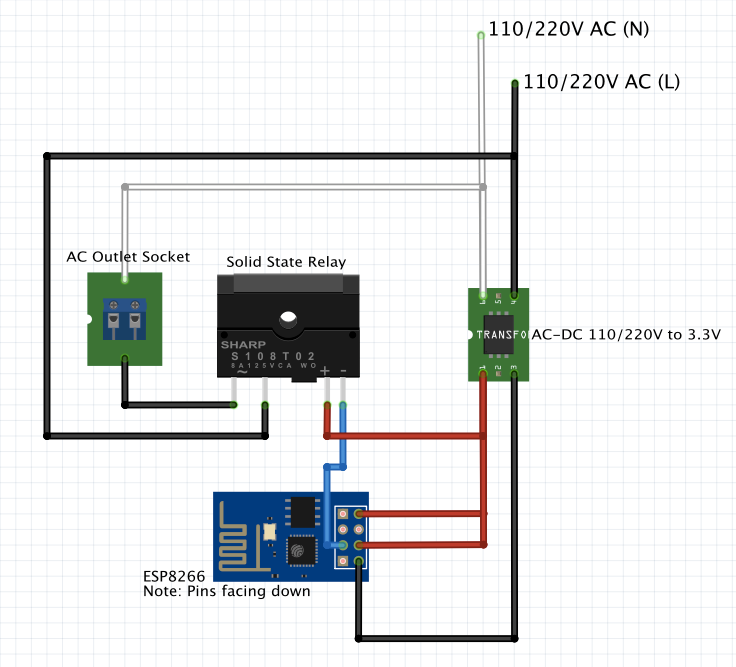

Solid state relay wiring diagram for cut out. Designed with attention to every detail idec relays and timers go the extra mile in performance and dependability. Solid state relays deliver the same result but dont have the mechanical components. The cut out relay allows voltage to flow to the battery so it can charge and maybe most importantly it doesnt allow voltage to flow from the. Solid state relay 3pst no 55 a 660 vac panel screw zero crossing check stock lead times 26 in stock for same day shipping.

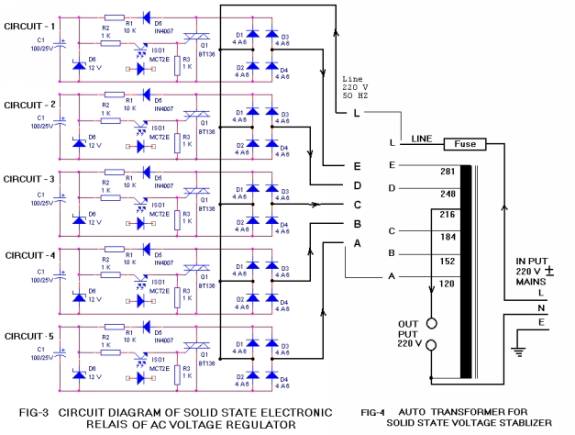

If the power factor of the load is low guideline. This gn series panel mount relay features direct bond copper substrate for superior thermal performance led indicator clearly identifies the relays input status. Mechanical relays use an electromagnetic coil and a physical switch. Three phase solid state relays their application in three phase motor circuits by paul bachman fellow engineer dr.

When you apply a voltage the switch activates. Mechanical relays and solid state relays. Over the years idec has introduced many new innovations to its family of relays. Order before 8pm est standard shipping mon fri.

Instead they use electronic components to do the same job. Bussed power lead frame. Idec produces a wide selection of interface power solid state and pcb mount relays to fit your application requirements. For example if you use 4 inch deep wiring trays leave 4 inches of empty space above the relay.

Abstract three phase solid state relays ssrs have been available since shortly after the introduction of single phase ssrs in 1970. Nu rex model a ford cut out the heat sink makes the difference originally the model a ford used a generator to maintain battery charging and the device that controlled the connection and disconnection to the battery was properly called a reverse current cut outthis device connects the battery to the electrical system when the generator voltage initially exceeds 65 volts and disconnects. Back to back scr output for heavy industrial loads. Solid state relays do not have to energize a coil or open contacts.

They require lesser voltage for switching and turn on and off faster because there are no physical parts to move. Cosf04 max the delay in the load current phase will increase relative to the load power supply voltage phase and a large transient voltage dvdt will be applied to the solid state relay when it is about to turn off ie the load current is near zero resulting in the possibility of the solid state relay not being able to turn off. All solid state relays are capable of running at full rated power with proper heatsink however it is strongly suggested that they be used at no more than 80 power to provide a safety margin in case of higher than expected volage temperature. Oscar montero rd manager and doug sherman fsae manager crydom inc.

Although the absence of contacts and moving parts means that solid state relays are not subject to arcing and do not wear out.