Wire Harnes Lacing

Getting electrical signals from point a to point b is pretty standard thingput a piece of copper wire between a and b and the job is done.

Wire harnes lacing. The wiring harness manufacturers association is the only trade association exclusively representing the cable and wiring harness manufacturing industry. Connectors shall be straight right angle or flange mount. How to avoid common wiring mistakes and correctly wire your car electronics jays tech tips 30 duration. Whma membership has impacted our organization through networking with members and suppliers across the country.

Lacing cord is made from a waxed nylon and is very strong. Wire bundle tying techniques. The use of right angle connectors shall be minimized and restricted to applications where stress free mounting of the cable assembly can be assured. One minute short showing how to tie lacing cord into a spot tie around a cable bundle.

String ties on a wire bundle are most acceptable substitutes for nylon tye wraps personally i prefer string ties over tye wraps for a finished product. Part of a series showing basic electronics skills. The cables are bound together by a durable material such as rubber vinyl electrical tape conduit a weave of extruded string or a combination thereof. Tye wraps leave a bulky.

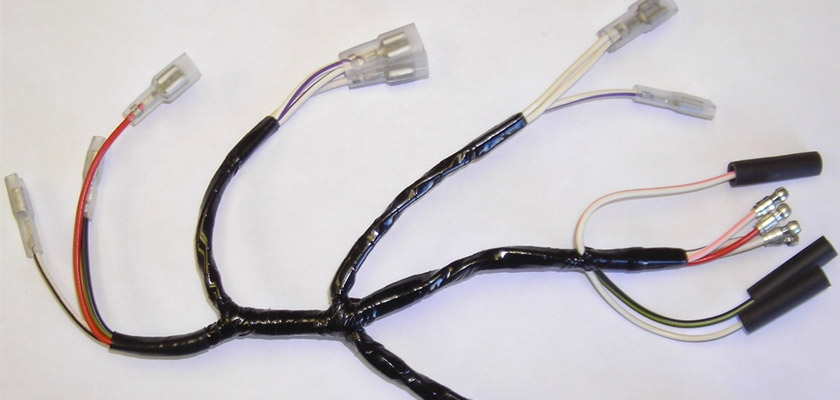

A cable harness also known as a wire harness wiring harness cable assembly wiring assembly or wiring loom is an assembly of electrical cables or wires which transmit signals or electrical power. After all the full automation of these processes complete with integrated quality monitoring is the only way to assure maximum quality and efficiency. Mil spec or military specification has become the buzz word in motorsport electrical harness construction. Cable and harness general requirements cont preferred.

Fully automatic block loading and wire harness manufacturing will become increasingly important in the future. Cable lacing is a method for tying wiring harnesses and cable looms traditionally used in telecommunication naval and aerospace applicationsthis old cable management technique taught to generations of linemen is still used in some modern applications since it does not create obstructions along the length of the cable avoiding the handling problems of cables groomed by plastic or hook. A century of development has left us with increased specialization in wiring connection devices and everything in between point a and b.