Wire Harnes Manufacturing Proces

After all the full automation of these processes complete with integrated quality monitoring is the only way to assure maximum quality and efficiency.

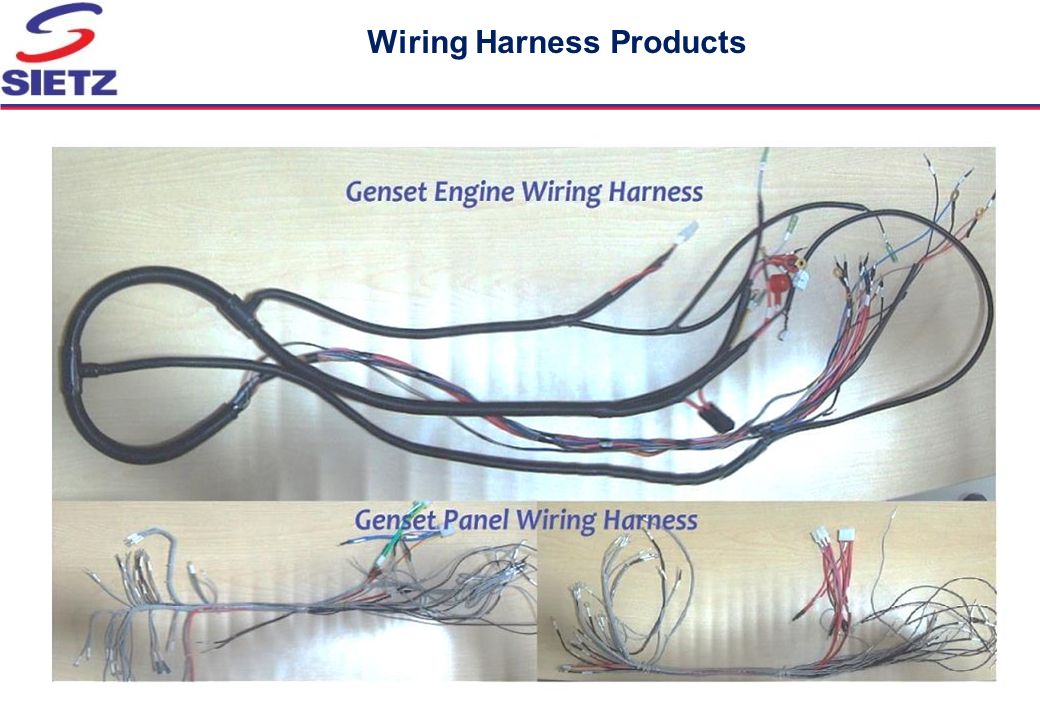

Wire harnes manufacturing proces. Read how this cable and wire harness assembler took lean manufacturing to the next level. Nonetheless as the demand for wire harnesses and cable assemblies grow manufacturing of these components continues to expand. A history of innovation. Thus the extraordinary variety of wires has been a major factor that hinders the automation of wire harness production.

Whether it is developing e commerce platforms to make it easier to work with us or creating a npi new product introduction process that helps our customers get to market faster or the other 10 new projects we have in process we must focus on building. There is a mystery of wire harness manufacturing. The wiring harness manufacturers association is the only trade association exclusively representing the cable and wiring harness manufacturing industry. To resolve this inspection challenge and meet the desired parts per million rates the manufacturing team members came up with a unique solution.

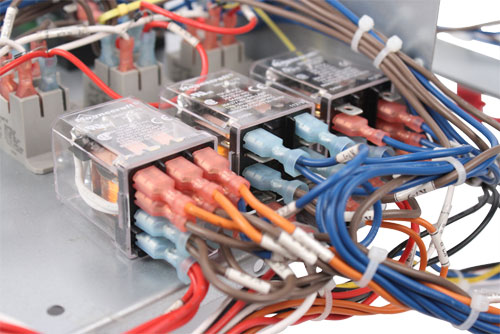

When it comes to designing and manufacturing wire harnesses and wire assemblies we dont cut any corners or sacrifice any quality. Fully automatic block loading and wire harness manufacturing will become increasingly important in the future. Safety is after all our number one priority. The equipments in workshop should be apt those which can handle the emission process.

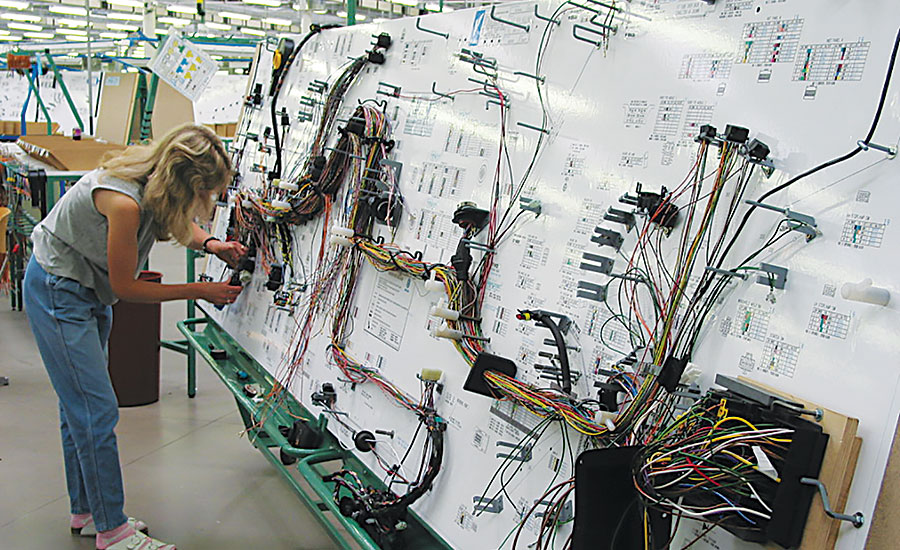

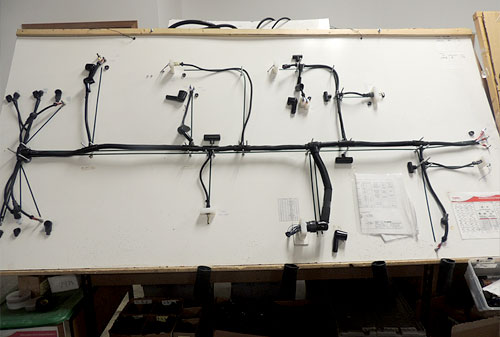

Today at epec the customer comes first and everything we do must be put through that filter. The wire harness manufacturing process is time consuming difficult and task oriented. We design and manufacture only the highest of quality wire harnesses and wire assemblies to the highest of safety standards. In conventional wire harness production hundreds of va rieties of wires having different sizes kinds and colors of core and insulation are cut and terminal crimped sub assembled and assembled to make wire harness prod ucts.

Manufacturing wire manufacturing process. Usually zero is seen as a very small. Arrow electronics a producer of component assemblies discrete wiring simple and complex harness assemblies molded on cable ends and mechanical subassemblies has been undergoing a transformation. Whma membership has impacted our organization through networking with members and suppliers across the country.

Wire harness manufacturing process. Precision cable assemblies pca has a continual wire harness manufacturing process improvement program embedded in each of its manufacturing facilities. For example the largest physical size that is seen on the measuring plates above is a size zero.