Wiring Harnes Documentation

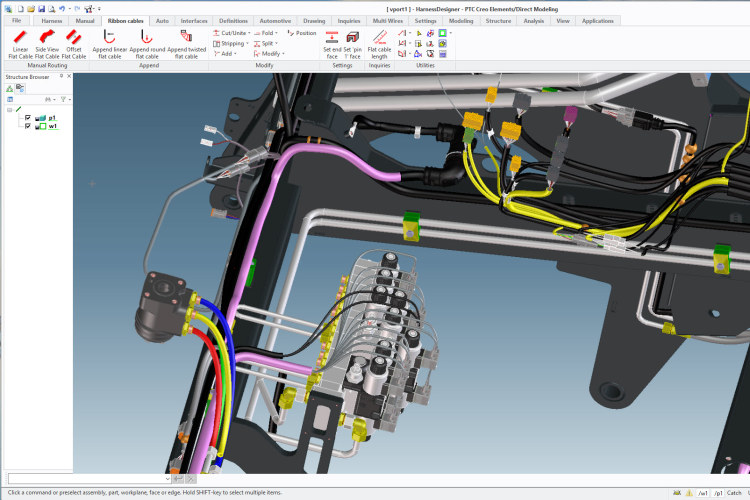

Due to the shared database in one integrated model wiring harness engineers can use the data of the architecture design to elaborate the wiring harness in detail.

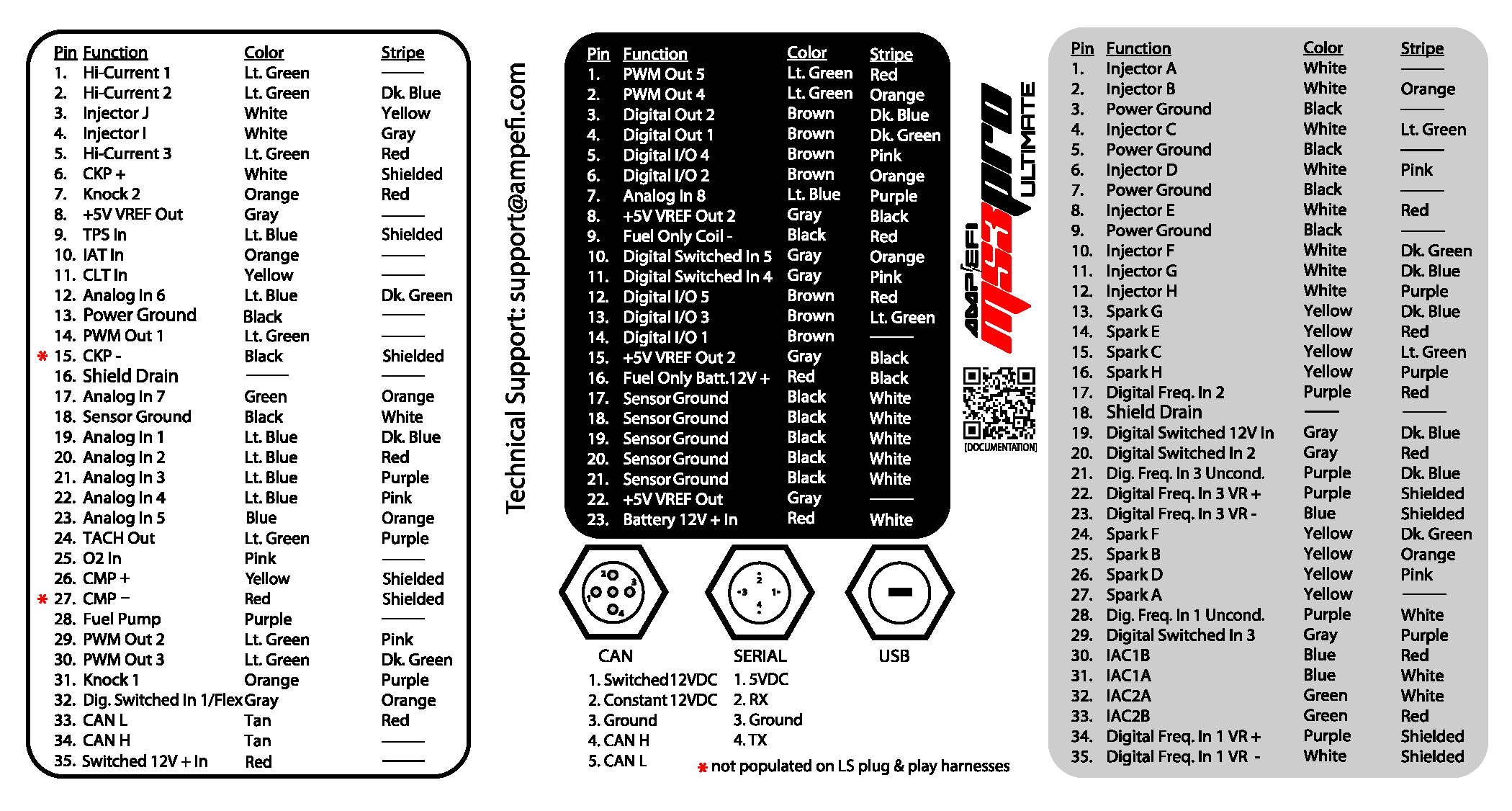

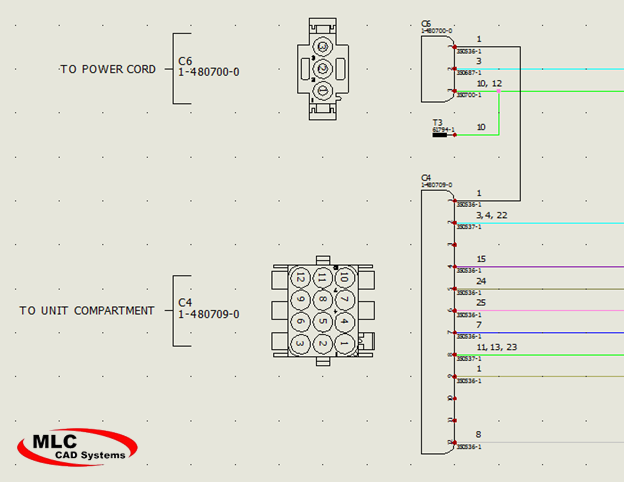

Wiring harnes documentation. Preevision supports a comprehensive development from architecture design to series production. The key challenges with wire harness engineering are the combination of mechanics and electronics as well as ensuring correct and consistent data. The next piece of information you need is the wiring harness military specification that most military aircraft comply with. From transferring connection information from eplan platform and intuitive routing to the creation of manufacturing documentation.

In return architects can use wiring harnesses of the series production for optimization. It is always a good idea to document your work. May be required in other ford vehicles as well as land rover and jaguar. This specification covers information such as.

Required globally for ford transit connect and ford transit full size vans. And asian vehicles such as honda mitsubishi nissan toyota kia and hyundai. Obdii extension t harness for the go device. Wiring harnes post by rubone sat mar 21 2020 444 pm debbie palmer is bruces wife she sells on ebay as watertowngrl however she is very busy right now with the upcoming release of volume iii of how to restore your harley davidson bruces books.

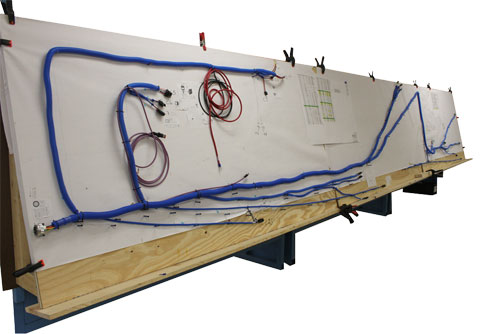

Wiring boards and electronic assemblies nasa std 87391a workmanship standard for surface mount technology nasa std 87392 with change 1 soldered electrical connections nasa std 87393 with change 3 crimping interconnecting cables harnesses and wiring nasa std 87394 with change 5 fiber optic terminations cable assemblies and installation. Eplan harness prod is a leading solution for the efficient design and documentation of cables and wire harnesses in 3d and 2d. Wiring harness software reinvented rapidharness is a full lifecycle cad solution built for designing production ready wire harness schematics. Whether youre working on quick test articles or aerospace grade drawings rapidharness will revolutionize the way you work.

This specification is sae as50881 at one time it was mil std 5088 wiring aerospace vehicle. Use eplan harness prod for the efficient design and documentation of cabling and wire harnesses in 3d. Wire current carrying capacity how wires are identified. The drag and drop drawing interface means designers can quickly and easily create high quality drawings as well as all the documentation needed for production.