Mig Welding Equipment Diagram

It is a process developed in the 1940s and is considered semi automated.

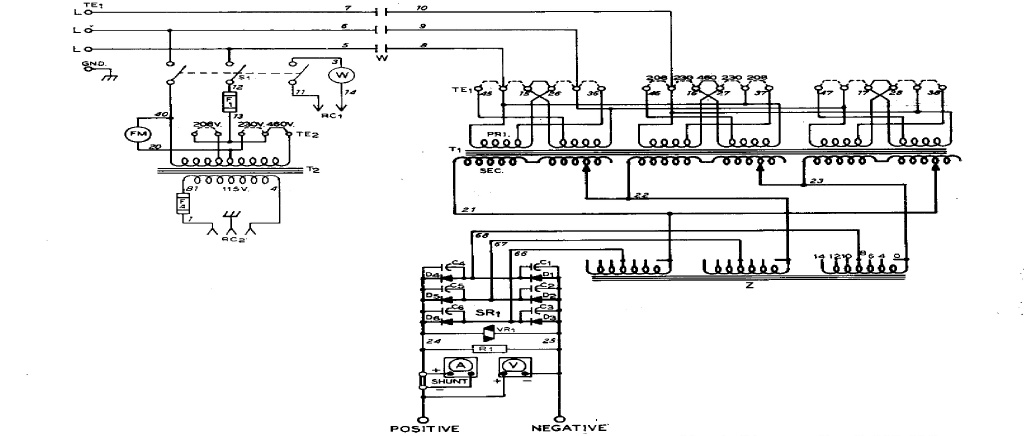

Mig welding equipment diagram. There isnt much going on inside this part of the welder so its worth it to take just a minute and familiarize yourself with. Mig welding is an abbreviation for metal inert gas welding. It is constant voltage power source whose one terminal is connected with the welding gun and the other is connected to the workpiece. Gas metal arc welding gmaw sometimes referred to by its subtypes metal inert gas mig welding or metal active gas mag welding is a welding process in which an electric arc forms between a consumable mig wire electrode and the workpiece metals which heats the workpiece metals causing them to melt and join.

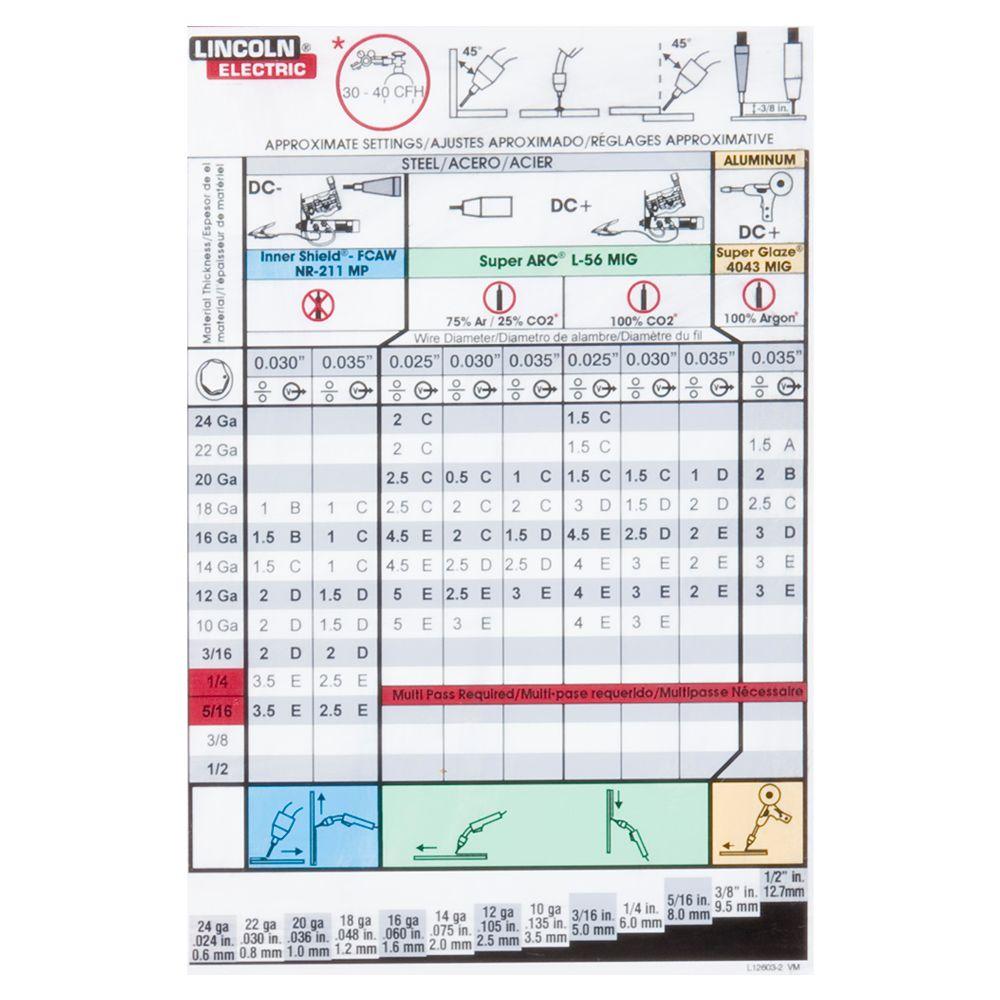

If you like this article dont forget to share it on your social networks. Current and voltage settings for dip and spray transfer mode and recommended welding glass shade numbers are presented. It provides continuous wire feed metal electrode during welding operation. The various equipment that is used in gmaw or mig welding process are.

Promax is a division of saffer plumbing hardware. The standard mig gun is nothing more than a cable with a gas feed system that has a remote wire that is connected to the trigger. Along with the wire electrode a shielding gas feeds through the welding gun. The power source wire feed system conduit gun and protective equipment for migmag welding are described.

Plasma welding machines accessories and consumables gas welding accessories safety gear equipment service and repair of welding machines product training. A welding power supply. If you have any query regarding this article ask by commenting. It contains a wire electrode and a shielding gas supply.

A mig welder has a couple of different parts. This means that the welder still requires skill but that the mig welding machine will continuously keep filling the joint being welded and electrodes do not need to be changed out between welds. A wire feed unit. Standard mig welding guns spool feed mig gun python push pull mig gun the standard mig guns.

The welder inside the welder you will find a spool of wire and a series of rollers that pushes the wire out to the welding gun.