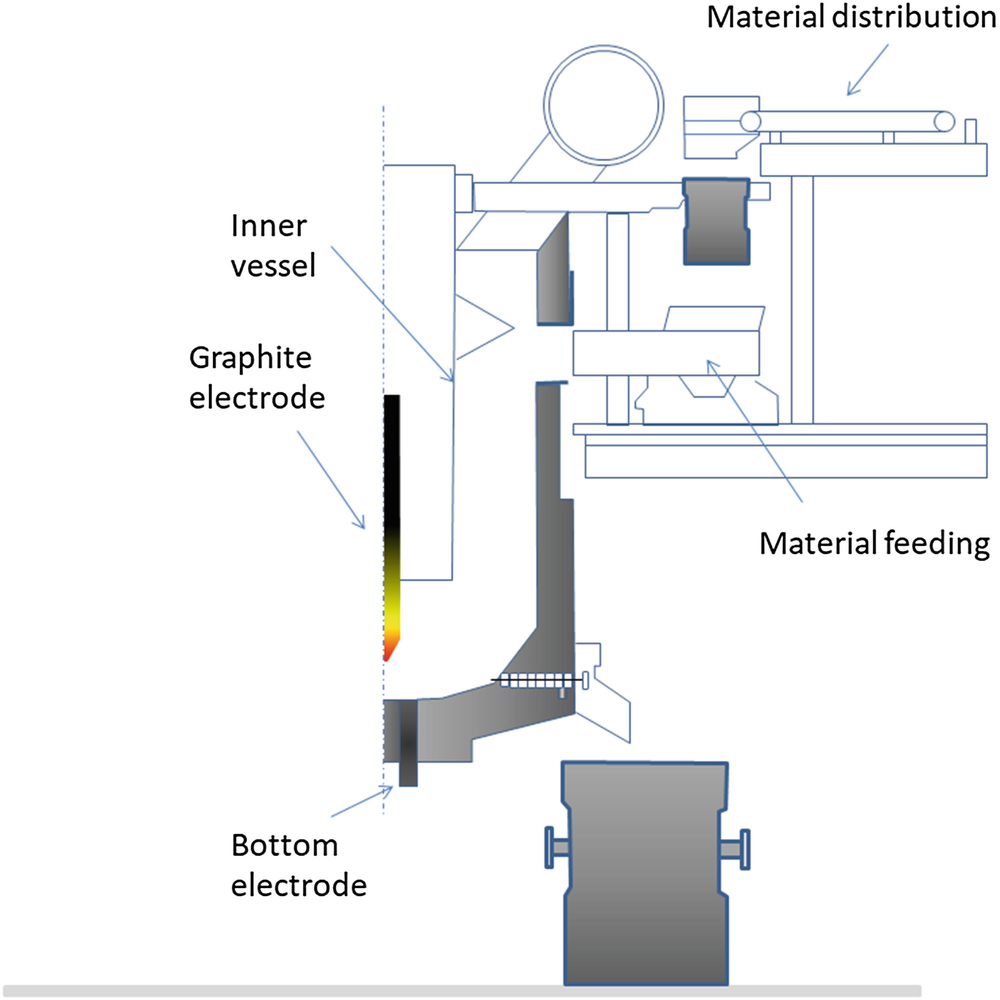

Schematic Diagram Of Electric Arc Furnace

Carrier provides technical and marketing literature to support all of its products.

Schematic diagram of electric arc furnace. Thyssenkrupp steel tubes photo. Down to about 1 mm or even down to 01 mm in the case of cupola dust foundry dust electric arc furnace dust and paint pigments. It has similar functionality to an electric furnace but with two major benefits. An electric arc furnace eaf is a furnace that heats charged material by means of an electric arc.

These improvements to the processing of scrap steel comprised of larger more efficient and higher capacity furnaces. Standard ac with standard furnace control wiring standard furnace standard thermostat standard ac condenser 1st stage heat white 24 volt fan only operation common air conditioning ac contactor control board 1 this diagram is to be used as reference for the low voltage control wiring of your heating and ac system. This is the beginning of the electric furnace series with a look at the parts of the furnace. Conductive electrode arm with lifting mechanism level water cooled electrode arm feed hole and discharge hole the operation is controlled by control box.

A 100t furnace would process the scrap in about an hour using a transformer of 60mva capacity. Salzgitter the process shown above is illustrative only and is not designed to show the steelmaking process in detail. Industrial arc furnaces range in size from small units of approximately one ton capacity used in foundries for producing cast iron products up to about 400 ton units used for secondary steelmakingarc furnaces used in research laboratories and by dentists may have a capacity of only a few. The electric arc furnace works twice as fast if powered using tier 2 power.

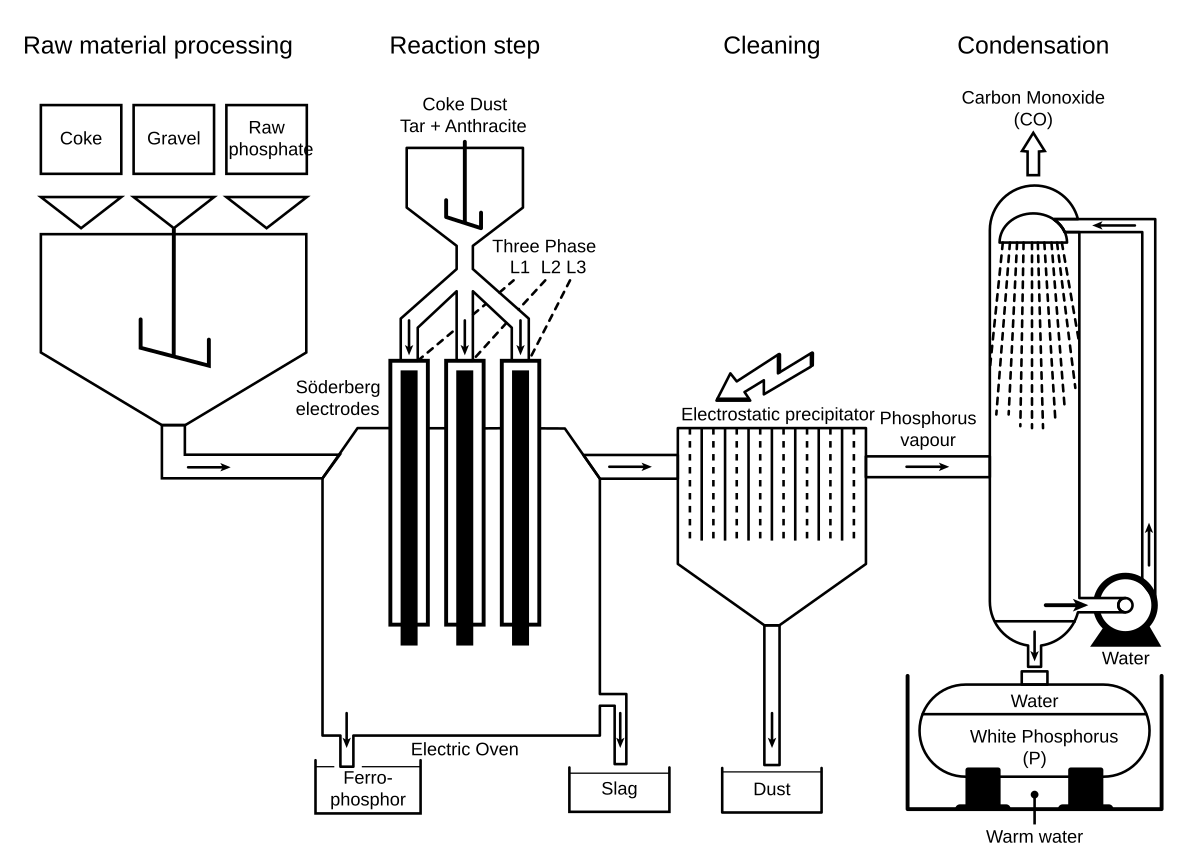

4719 c gives its vector diagram. Aluminum furnace schematic wiring diagram schematic name. Indirect electric arc furnace fig. Figure 4424 shows the schematic diagram of this process.

Induction furnace electrical circuit. An electric arc furnace eaf is a furnace that heats charged material by means of an electric arc. The electric arc furnace is a tier 2 machine introduced in galacticraft 3. Not all steel plants produce all of the products shown in this diagram.

This video is part of the heating and cooling series of training videos made to accompany my websites. 200 kg of scrap ferrous metal was melted in an electric arc furnace the schematic diagram of the gear box that was designed is shown in fig2 illustrating the fusion in induction furnace. The second world war saw a steep increase in the use of these furnaces leading to the modern electric arc furnace design operation and working principles. Doubled ingot production from smelting ores and faster speed than an electric furnace.