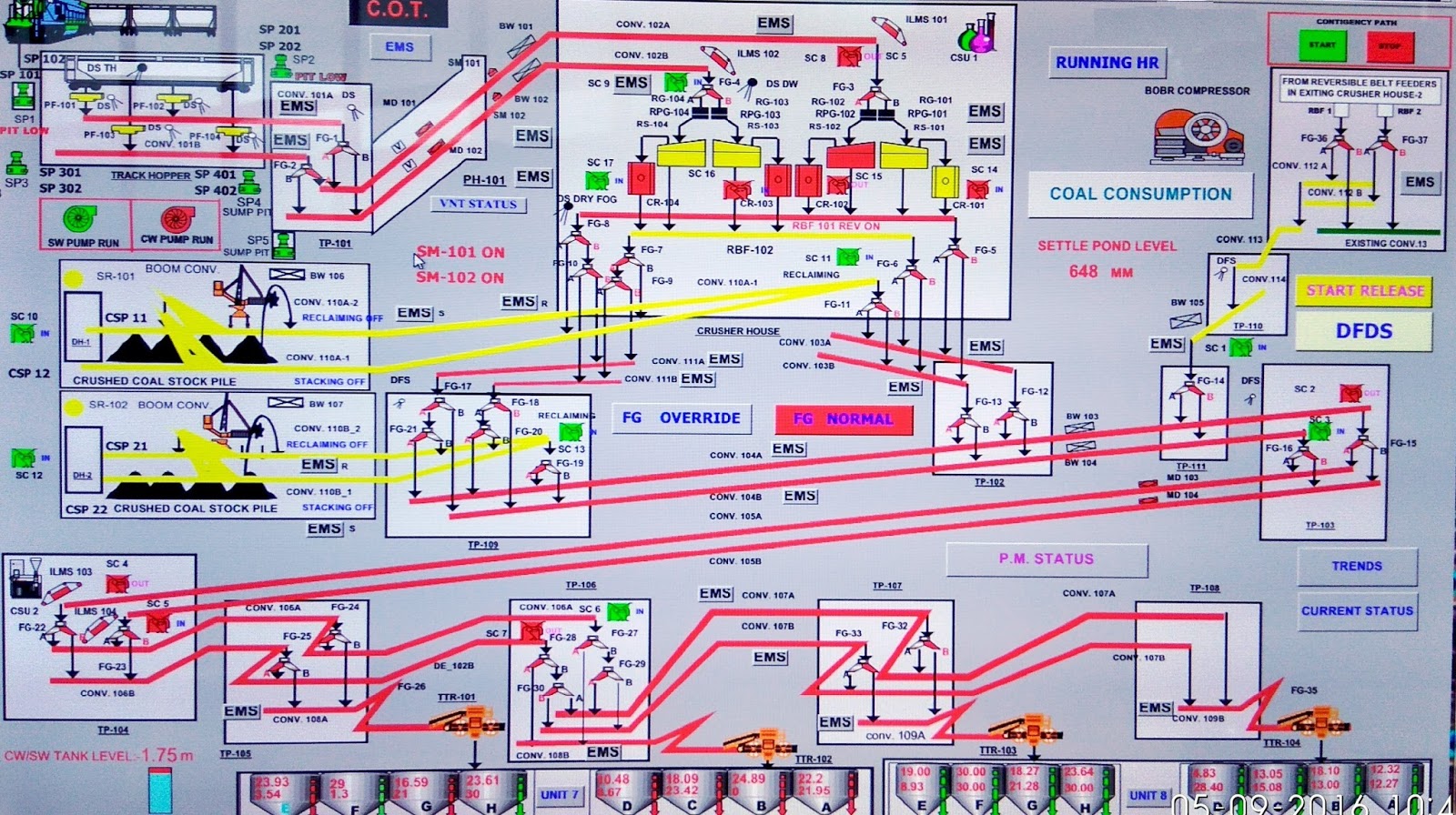

Simple Coal Fired Power Plant Process Flow Diagram

A coal fired power station is a type of fossil fuel power stationthe coal is usually pulverized and then burned in a.

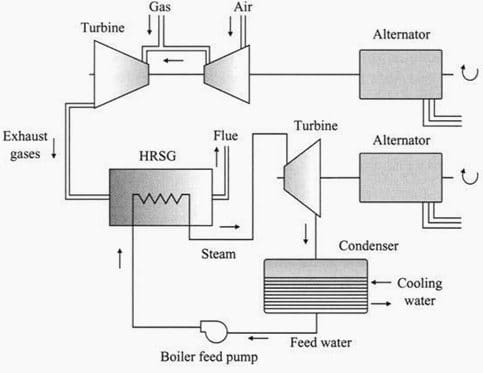

Simple coal fired power plant process flow diagram. A combined cycle power plant uses both a gas and a steam turbine together to produce up to 50 percent more electricity from the same fuel than a traditional simple cycle plant. Aquatic organisms and on the water resources of the region where the power plant is located 5 6. A report from the us department of energy 7 identified a total of 347 coal fired power plants from an analysis set of 580 plants as vulnerable to water demand andor water supply concerns. The coal power plant diagram shows the components of the plant and the different stages of transforming the chemical energy coal into electrical energy as.

We started with the boiler or the steam generation system. The coal fired process requires three different steps to turn energy released from burning coal to generating electricity for consumption. Typical coal based power plants operating at steam pressures of 170 bar and 570 0c run at efficiency of 35 to 38 with state of the art fossil fuel. A coal fired power station or coal power plant is a thermal power station which burns coal to generate electricitycoal fired power stations generate over a third of the worlds electricity but cause hundreds of thousands of early deaths each year mainly from air pollution.

Coal fired power plant diagram. As we supply the coal from coal bunkers via coal conveyors to be crushed into coal mills. Inner workings of a combined cycle power plant. Remarks on coal beneficiation process and diagram sub a coal flotation systems have been successful for recovery of both coarse and fine coal.

A simple cycle gas turbine achieves energy conversion efficiencies from 20 to 35. The energy efficiency of a conventional thermal power station is defined as saleable energy produced as a percent of the heating value of the fuel consumed. Coal fired power plants while producing power require a lot of water and produce a lot of pollutants like ash and co2. Learn how the process works as well as interesting.