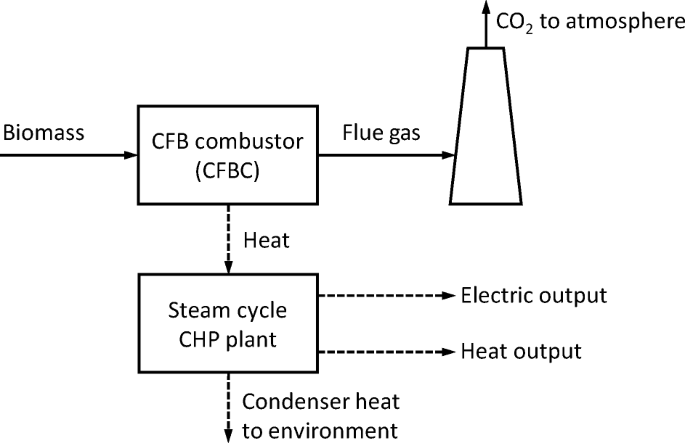

Steam Power Plant Flow Diagram

Water first enters the economiser where water is heated first.

Steam power plant flow diagram. Water is fed by the bfp boiler fed pump from water source like pond or reservoir. Khalil department of mechanical power engineering cairo university cairo egypt. See categoryprocess flow diagrams flow diagram of a steam cycle power plant. The closed in pressure p ci for which there is no steam flow and the condenser pressure p c for which there is no enthalpy drop.

These three most essential elements are coal air and water. The coal power plant diagram shows the components of the plant and the different stages of transforming the chemical energy coal into electrical energy as. As we supply the coal from coal bunkers via coal conveyors to be crushed into coal mills. Abstract the ef cient utilization of fossil energy in power generation together with low pollution in conventional thermal power plants is a topic that is gaining interest internationally.

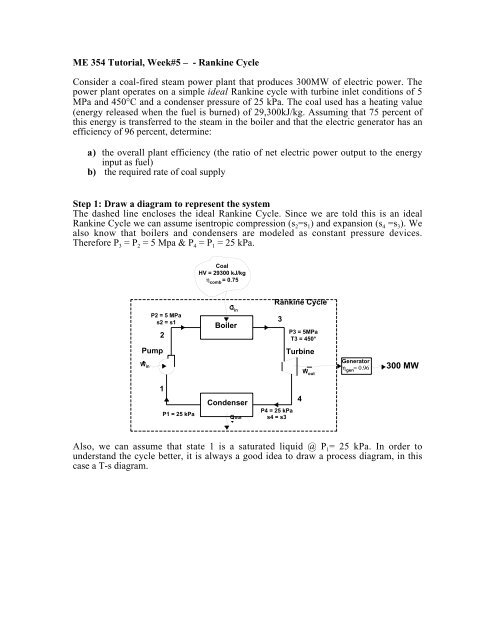

A thermal power generating plant works based on rankine cycle. Chapter 4 steam power plants e. A process flow diagram pfd is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment. The air filter is attached at the inlet of the compressor where air gets.

There are mainly three primary inputs given to a thermal power generating plants for producing electricity. Steam power plant schematic diagram. Coal is fuel here because we are going to draw the flow diagram of. The steam power plant is the important source to produce the electricity.

Steam power plant constructionworking advantages and disadvantages with diagram august 9 2016 april 23 2018 pankaj mishra 6 comments power plant thermal engineering thermodynamic. The main components of a gas turbine power plant are the compressor regenerator combustion chamber gas turbine alternator and starting motor. Although steam power station simply involves the conversion of the heat of coal combustion into electrical energy yet it embraces many arrangements for proper working and efficiencythe schematic diagram of steam power station is shown in the figure belowthe whole arrangement can be divided into the following stages for the sake of simplicity. There are two limits to the wellhead pressure.

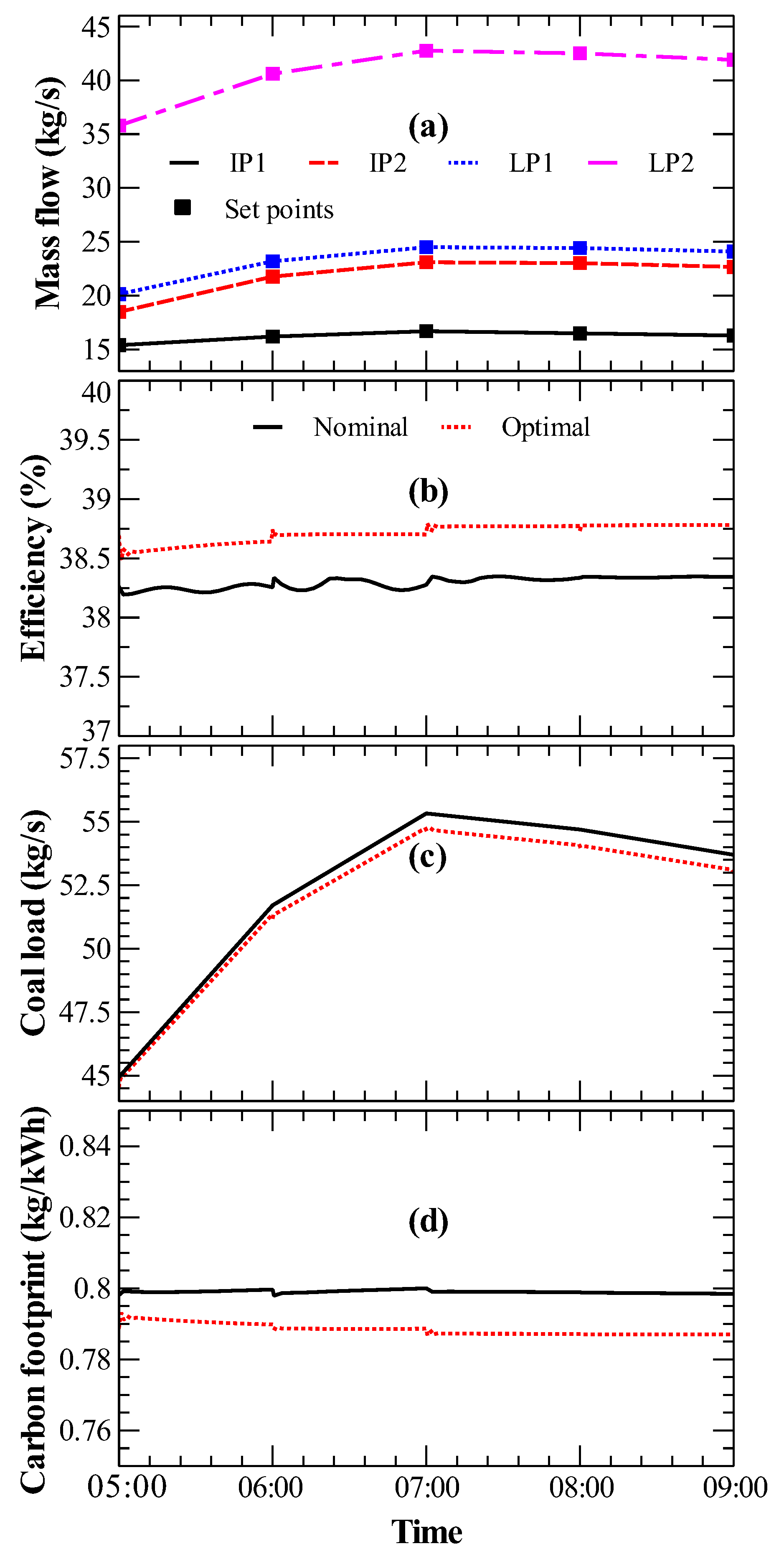

The turbine power is proportional to the product of the steam mass flow rate and the enthalpy drop d h shown for an ideal isentropic process for simplicity.